Kev kho cov dej cawv dub los ntawm Papermaking los ntawm Txau kom qhuav

Txij li feem ntau ntawm cov khoom siv raw rau pulping hauv Suav teb yog cov ntaub ntawv tsis yog ntoo fiber ntau (sau ntau dua 50%), alkali thiab acid rov qab txoj kev siv rau kev kho cov cawv dub hauv feem ntau cov ntawv zeb. Txawm li cas los xij, vim tias cov dej tsis zoo ntawm cov nyom nyom, ntau lub hlwb hauv cov cawv dub, siab viscosity thiab siab silicon cov ntsiab lus ntawm cov cawv dub, qhov kev ua haujlwm tiag tiag ntawm alkali rov ua haujlwm tsis zoo, qhov nruab nrab alkali rov qab tus nqi tsuas yog kwv yees li 60%, thermal efficiency, siab ua haujlwm thiab kev tswj xyuas nyuaj. Yog li ntawd, nws yog ib qho nyuaj kom daws tau tag nrho cov teeb meem ntawm cov dej cawv dub nyob rau hauv straw pulp cog. Raws li kev tshawb fawb thiab kev loj hlob ntawm cov tshuaj tsuag kom qhuav thiab evaporation concentration rau ntau xyoo, thiab ua ke nrog kev tsim thiab kev ua haujlwm ntawm kev qhia txog ib qho system rau evaporation thiab concentration ntawm cov cawv dub nyob rau txawv teb chaws, peb lub tuam txhab tau npaj thiab ua raws li cov txheej txheem tsis muaj kuab paug paug ntawm kev kho dej cawv dub.

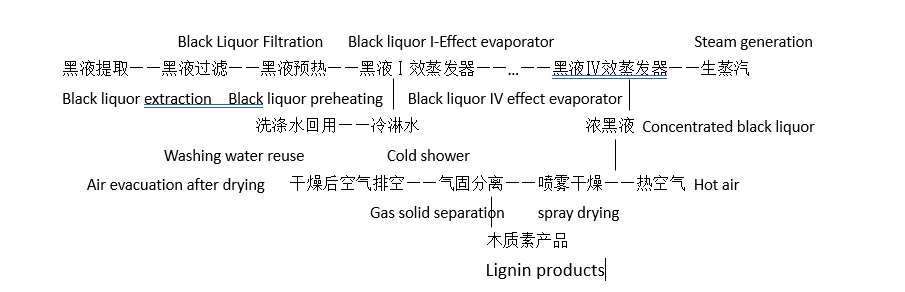

Condensed dej thiab concentrated dub cawv tawm los ntawm evaporator, condensate yuav siv tau raws li cov dej ntxuav, thaum concentrated dub cawv nkag mus rau tshuaj tsuag kom qhuav. Thaum lub sij hawm cov txheej txheem ziab qhuav, cov hmoov av tawm ntawm lub tshuab ziab yog tsawg dua 100 ~ 150 mg / m3, uas tuaj yeem ua tau raws li lub teb chaws emission qauv. Tsis muaj cov kua khib nyiab tawm, thiab cov khoom lignin tau txais tib lub sijhawm. Tag nrho cov txheej txheem ntawm kev kho dej cawv dub tsis yooj yim nrhiav tau, thiab tsis muaj cov pa khib nyiab thiab cov kua dej pov tseg hauv tag nrho cov txheej txheem, kom ua tiav lub hom phiaj ntawm xoom paug paug ntawm kev kho dej cawv dub. Daim ntawv ua cov cawv dub yog ua rau cov khoom lag luam lignin rau kev siv dav. Nws yog dav siv nyob rau hauv pob zeb dej reducer, thee dej slurry dispersant, asphalt emulsifier, ceramics, roj zoo exploitation additives, thiab lwm yam, thiaj li tshem tawm cov kev puas tsuaj rau lub ecological ib puag ncig, tsim ib puag ncig-phooj ywg, ntuj thiab kev sib haum xeeb txoj kev loj hlob, thiab tiag tiag paub kev sib sau ntawm kev lag luam kev pab cuam, ib puag ncig cov txiaj ntsig thiab cov txiaj ntsig kev sib raug zoo.

Zero paug txheej txheem khiav ntawm extraction dub cawv

1. Khoom siv:papermaking dub cawv thiab cawv liab

2. Cua inlet kub:280 ℃ ~ 430 ℃

3. Cua qhov hluav taws xob kub:110 ℃

4. Cov hmoov qhuav qhuav:1000kg / H ~ 4000kg / h

5. Khoom siv:40% ~ 50%

6. Thaum tshav kub kub qhov chaw:Kev raug tua hluav taws xob kub tawg hluav taws kub tawg nrog kev teeb tsa, chav tsev superheated, thiab tuaj yeem hloov raws li cov neeg siv khoom)

7. Atomization hom:kev kub ceev centrifugal atomizer yog saws

8. Cov txheej txheem cua sov:ncaj qha hluav taws xob hluav taws xob hluav taws xob hluav taws xob qhov cub (nrog plaub-theem teeb tsa chamber kom tiv thaiv Mars los ntawm kev nkag mus)

9. Cov ntaub ntawv rov qab:Thawj cyclone plua plav tshem tawm thiab cov dej ntub dej ntub dej ntxuav cov plua plav yog siv, nrog tus nqi rov qab ntawm 99.8%, uas yog nyob rau hauv txoj kab nrog lub teb chaws tus qauv Emission.

10. Txais:Centralized txais yuav tau txais. Hauv qab ntawm tus pej thuam thiab cov hmoov uas tawm ntawm lub tshuab nqus plua plav cua daj cua dub raug xa mus rau qhov sib npaug ntawm cov khoom siv cua ntim khoom ntim yuav tsum tau nqa tawm hauv lub warehouse ntawm lub rooj cob qhia ntim khoom.

11. Kev tswj hluav taws xob:PLC tswj qhov kev pab cuam tau txais yuav. (automatic tswj ntawm huab cua inlet kub, huab cua qhov hluav taws xob kub, roj kub thiab roj siab tswb ntawm atomizer thiab tsis zoo siab tso saib nyob rau hauv pej thuam)